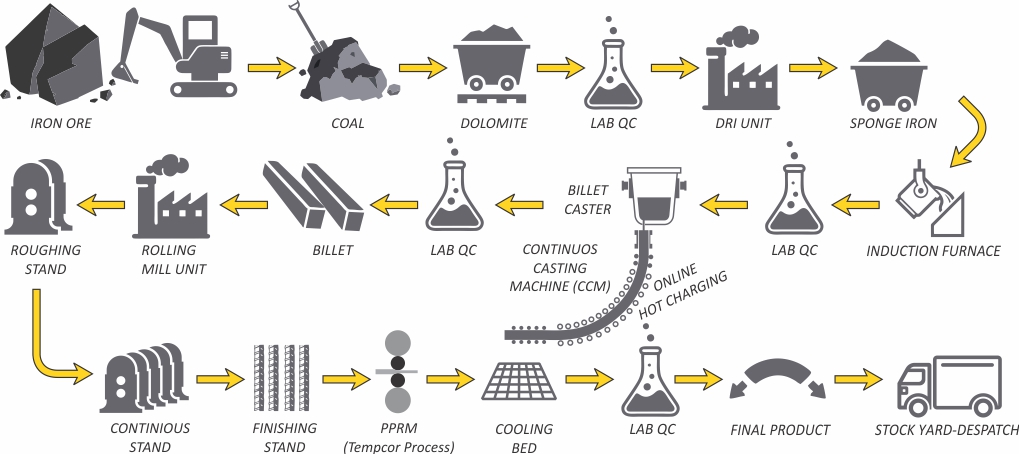

Shrishtii’s Thermo Mechanically Treated Steel or TMT is manufactured through the

TEMPCORE process at Nav Durga Plants; the bars range from 8mm to 32mm in

thickness and have high bend quality, high temperature resistance and low carbon

quality. Our samples undergo rigorous testing in weight, length and dimension as

per the guidelines mandated in IS 1786.

Shrishtii TMT Bars are engineered to contribute to the construction of a

stronger India, providing excellent strength and reliable performance.

Manufactured using a standardized process, Shrishtii bars are made from

carefully selected high-quality raw materials for an ANDAR SE MAZBOOT

construction experience.

By employing advanced manufacturing techniques and quality control measures,

Shrishtii TMT ensures that their bars are of the best-in-class quality. Fe 550 D

Bars can be used across a range of residential, commercial and multi-storey

project. They offer greater tensile strength and greater ductility which are

specially manufactured to provide stability to high-rise project, while

resisting load better.